Frequently asked questions.

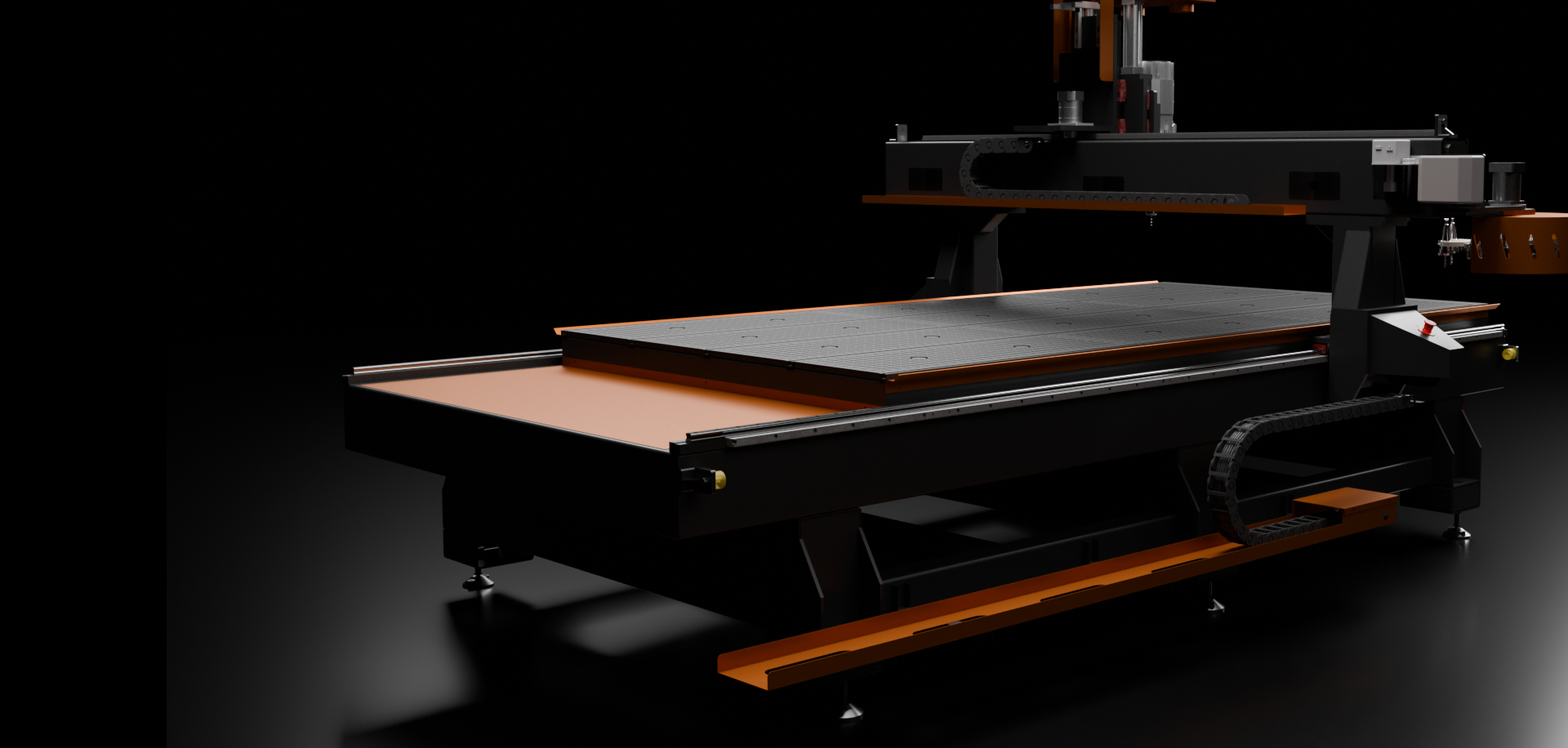

WHAT DOES A CNC ROUTER DO?

A computer numerical control (CNC) router can save you time and money when it comes to precise cutting of manufacturing materials such as aluminum, plastic, wood, dense foam or vinyl. Instead of a human operator directly controlling the machine, its movements are calculated and carried out by a computer on a pre-programmed path along the X, Y, and Z axes.

HOW MUCH DOES A CNC ROUTER COST?

The price of a CNC router machine largely depends on the material you're using in production, as well as the size of the cuts you're planning to make. You can get a small, wood-cutting CNC machine for as little as $2,000, but remember that the cheapest options may require more maintenance and can break faster than some of the more sophisticated models. Reach out to us for a free quote, or learn more about how to get help to finance equipment that will fully meet your CNC router needs.

HOW TO CHOOSE THE RIGHT CNC ROUTER?

You should take your time to carefully assess the capabilities and pricing of each CNC router option you're considering. Not all manufacturing facilities are the same, therefore it is recommended that you take the following factors into account:

The size of your site: You should have an estimate of how much space you'll have for your new CNC cutter. State-of-the-art equipment won't be of much use to you if you don't have enough room for a dedicated workstation!

Your final product: Are you going to be cutting up a variety of materials? How big are your products? How many of them are you looking to manufacture every day? These are just some of the things you should consider when choosing the appropriate CNC router.

Your budget: While you probably don't want to go for the cheapest option available, your budget is an important factor to consider. Just like with any product, CNC cutters come in all shapes, sizes and price points. Reach out to an expert for an opinion, and do your own research online before you place your order.